Waterside Training Limited based in St Helens, Merseyside is a specialist training provider, delivering high quality engineering and manufacturing apprenticeships and offers a broad range of bespoke industrial training programmes to various industry sectors throughout the North West..

In collaboration with our employers we have designed apprenticeship and technical training programmes to equip the next generation of technicians and engineers with the skills required for the future.

Aspiring apprentices for their future career

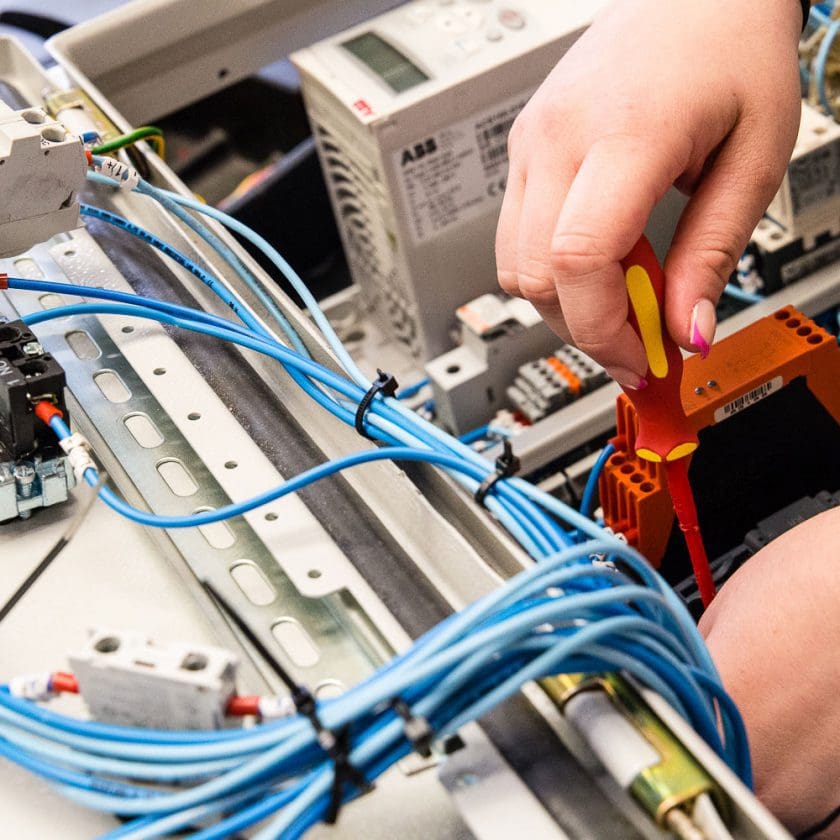

At Waterside Training, we will coach, train and teach you the skills, knowledge and behaviours required to successfully achieve your ambition of becoming a skilled engineer or technician. By embarking on an apprenticeship with us, you will receive the very best practical skills training across a broad spectrum of engineering disciplines alongside technical and higher-level academic qualifications. You will learn from highly qualified and experienced engineering tutors using industry standard equipment, in realistic working environments, as well as the on-the-job training which you will receive within your workplace.

Find out more →

Invest in a bright future

Investing in apprentices can help to build your workforce and retain valuable skills from your existing employees. Hiring apprentices is an effective way to create and grow a sustainable talent pipeline of motivated, skilled and qualified engineers and technicians for the future. By aligning your business skill needs with the training we provide, alongside the apprenticeship standards, you can secure and grow your workforce into an ambitious team improving organisational retention and productivity.

Find out more →

Develop your workforce

Waterside Training offers a wide range of technical and specialist courses to deliver Electrical, Mechanical, Welding, Health, Safety & Management training programmes to assist in the upskilling of your existing workforce or train new employees whilst meeting legal requirements and increasing business productivity.

Find out more →

Working in Partnership with

Testimonial

Vanderlande are proud to be partnered with Waterside Training as our principle training provider in the Northwest to deliver technical training to our teams, especially the Mechanical Maintenance VRQ L2 programme.

The mixture of technical knowledge and practical elements which our delegates have received over the course of the year combined to make a fulfilling experience. The course was engaging with many opportunities to participate and lots of relatable examples that we were able to bring back to site. This was found after a full site tour by the Waterside team to expertly devise the best course to deliver our teams with knowledge of the process and equipment on site.

We have now trained at least half of the Engineering Support Operatives across our four shifts with all the teams and site reaping the rewards in maintenance completion and system performance through the continued support given and putting into practice the skills they learnt. The tutorship given is professional with tailored delivery to the differing knowledge of the attendees on each course, which ultimately shows how diverse the styles of teaching are at Waterside Training.

This has set our Engineering Support Operatives on an Engineering and Technical pathway to offer hands on support for our teams of Service Technicians to deliver planned and reactive maintenance across the largest warehouse in both Vanderlande’s and Asda’s UK portfolio.

We look forward to upskilling our single trade Service Technicians in the near future with expertly tailored courses to have a truly Multi-Skilled Engineering team at our disposal.